When it comes to hauling bales, most hay producers assume any trailer will get the job done. That thinking costs you time and money. In a commercial operation, your round bale hay trailer is not just a piece of equipment—it’s a key player in your harvest logistics.

If you’re moving hundreds of round bales daily, choosing the wrong trailer can cut efficiency by 30% or more. That’s time you’re not getting back—and profit you’re leaving in the field. Let’s update you more on the details –

Let’s face it—loading bales manually or using outdated equipment is a bottleneck in your workflow. For high-volume producers, every trip between the field and barn has to be optimized for speed, safety, and stacking efficiency.

Your round bale hay trailer should be engineered for quick loading, smooth highway travel, and easy offload into storage. It’s not about what works—it’s about what works best for your operation.

If you’re still relying on flatbeds or retrofitted utility trailers, you’re likely spending 35-40% more time per load versus using a custom-built inline or hydraulic trailer!

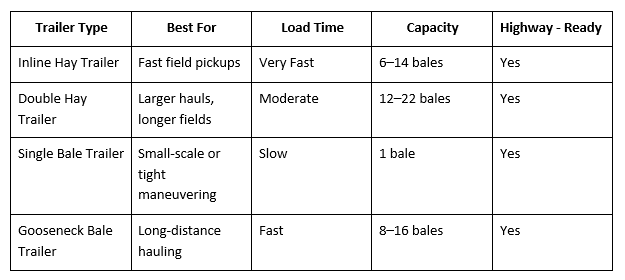

You can’t scale a commercial hay operation using small-farm equipment. Let’s break down the common trailer types that suit different field sizes and bale volumes:

Looking to scale up? A well-built inline hay trailer for sale is a smart investment. For big days and longer hauls, double hay trailers for sale might be your best bet. Handling small batches or limited access areas? A single bale hay trailer still has its place.

A solid round bale hay trailer doesn’t just move bales—it optimizes your entire harvest process. Look for:

• Shear-and-brake-engineered frames for heavy-duty loading

• Precision welded joints to endure tough field terrain

• Custom axle and driveline work for safe highway travel

• Powder-coated or zinc-treated finishes to prevent rust

• Adjustable loading arms for variable bale sizes

According to a 2023 USDA Agricultural Research Service study, 75% of large-scale hay producers say hay transport and stacking is their top bottleneck during peak season.

The average hay producer moving 400+ bales per day could save over 90 hours per season by switching to a purpose-built, multi-bale trailer.

Mass-market trailers aren’t built with your fields, bales, or crew in mind. That’s where custom fabrication plays a huge role—especially for operators who value reliability and efficiency.

Denning Machine Shop Inc. works directly with ag operations to build or modify trailers using:

• Industrial-grade welding and frame reinforcement

• Shear and brake operations for precise fitting

• Custom axle, bearing, and spindle setups

• Tailored lengths, ramps, and stacking configurations

Whether you’re building a new round bale hay trailer for sale, modifying an older unit, or upgrading to meet DOT transport standards—we provide custom parts and fabrication that hold up in the field and on the highway.

1. What’s the best trailer for high-volume hay operations?

An inline hay trailer or double hay trailer with hydraulic self-loading saves time, reduces labor, and handles large volumes efficiently.

2. Are round bale hay trailers road legal?

Yes—trailers designed for agricultural use with correct lighting, braking systems, and axles are road-legal in all U.S. states.

3. Can I retrofit my existing trailer?

Absolutely. A custom fabrication shop can modify frames, install new drivelines, and reinforce load points for higher volume handling.

4. How much weight can a typical bale trailer hold?

Most commercial round bale hay trailer units can handle 8,000–14,000 lbs, depending on axle configuration and build quality.

5. Where can I find custom trailers for my hay operation?

Denning Machine Shop Inc. offers fully customized round bale hay trailer for sale options, built to match your workflow and terrain.

A hay operation doesn’t run on horsepower alone—it runs on logistics. Every hour your team spends waiting on equipment is money lost. Whether you’re pushing 300 bales a day or 1,000, your trailer must match your operation’s pace and power.

Looking for double hay trailers for sale, a custom single bale hay trailer, or a purpose-built inline hay trailer for sale? You’re not buying a trailer—you’re investing in smoother, faster, and more profitable harvests.

And with Denning Machine Shop Inc., you don’t have to settle for off-the-shelf. We build what works—because your bottom line depends on it.

Want to take the load off your crew and put the weight on your trailer? Let’s build it right, the first time. Contact us today!