Tired of slow hay handling and frequent trailer repairs? You’re not alone. Farmers and ranchers across the U.S. are making the shift from generic models to custom inline hay trailers — and the results are worth the investment.

Whether you’re managing thousands of acres or a small-scale operation, the right inline hay trailer makes a big difference in loading speed, maneuverability, and overall durability.

Here’s why precision fabrication matters more than ever in modern hay transport.

Most off-the-shelf trailer for hay options are built to “fit all” — which often means they fit none perfectly. This leads to:

• Uneven loading and frequent rebalancing

• Poor road stability and inefficient axle configurations

• Structural wear under heavy or uneven bale loads

• Shorter trailer lifespan

But here’s where custom fabrication steps in. With precision welding, accurate measurements, and material choice tailored to your land and load, you get a trailer that works with you — not against you.

1. Enhanced Loading & Unloading Speed

Custom-fitted cradle angles and rail heights ensure faster bale positioning. Add automated or gravity-fed loading features, and you cut turnaround time significantly.

2. Better Field Maneuverability

Wide turns on soft terrain? No problem. Tandem axle systems and optimized weight distribution reduce rutting and boost traction — even when fully loaded.

3. Increased Trailer Longevity

Using reinforced steel frames, heavy-gauge tubing, and precision-cut components means less flexing, fewer weld failures, and more years on the field.

“All trailers are built the same.”

False. Materials, welding technique, and axle spacing directly affect load capacity and trailer wear.

According to a 2023 report by the USDA Agricultural Equipment Sector, farms using custom hay trailers saw a 15-20% improvement in bale handling speed compared to operations relying on mass-market trailers.

That’s more hay moved, more time saved, and less stress on your equipment.

Your land isn’t flat, uniform, or predictable — and your trailer shouldn’t be either.

Whether you’re hauling round bales on rough pastures or managing storage yards with tight turns, a custom-built round bale hay hauler gives you tailored load balance, braking response, and axle spacing.

“Customization is too expensive for small operations.”

Think again. While upfront costs may be slightly higher, the reduced maintenance, faster hauls, and increased lifespan often pay for themselves within 1-2 seasons.

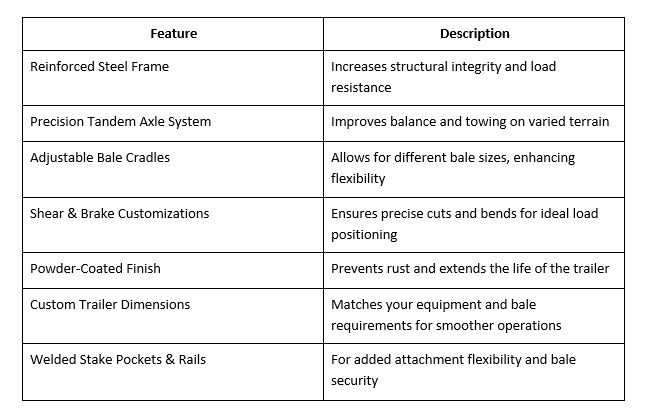

Our team specializes in precision welding, machine work, shear & brake operations, and CNC-cut trailer parts that ensure every inch of your trailer hay system meets industrial-grade standards.

We build them from the ground up based on your usage pattern, land conditions, and equipment.

Whether you need a 10-bale hauler, a tandem axle setup, or reinforced steel components — Denning Machine Shop Inc., with its range of options, is here to cater to all your requirements. Backed by industry expertise, we help farmers and ag-businesses scale efficiently and affordably.

1. What is an inline hay trailer?

A custom inline hay trailer is designed to carry hay bales in a straight line, maximizing loading efficiency and improving balance during transport.

2. Why choose custom trailers over standard models?

Custom trailers are optimized for your specific field, load type, and usage—unlike standard models that often lack durability and precision.

3. Can I get a trailer that handles both round and square bales?

Yes, through custom trailer dimensions and adjustable cradles, we can accommodate multiple bale formats efficiently.

4. Is a tandem axle system really necessary?

For rough terrain or heavier loads, tandem axles reduce stress on the trailer frame and improve towing stability—essential for heavy-duty farm equipment.

5. How long does it take to fabricate a custom hay trailer?

Lead times vary, but most builds are completed in 2-4 weeks, depending on complexity and material availability.

You already know that speed, safety, and durability matter. So why settle for one-size-fits-none? A custom inline hay trailer isn’t just equipment—it’s an efficiency multiplier.

With modern materials, precision fabrication, and farm-specific design, you’re not just saving time, you’re extending the working life of every component in your hay-handling operation.

Don’t let your trailer slow down your harvest. Let precision work for you.